Industry Best Practices for Using Safety Labels

Do you use safety labels to mark your products at work? Check out the best practices for safety labels in this week’s guide.

Different facilities have various needs and limitations, but all facilities have a common requirement – ensuring a safe workplace for all.

To enjoy a safe workplace, all your employees must understand the message conveyed by each safety sign and label on the premises. Here, in this guide, we help break down what are safety labels, how to use them, where to position them and more.

Several standard regulations specify the workplace rules and laws regarding safety labels. Right from product packaging to distribution of the product to the end consumer, these safety labels help in ensuring the safe transportation and safe usage of all these products. Safety labels are used for all products, including cosmetics, medicines, electronic gadgets, and even accessories and apparels.

Why are safety labels being given so much importance in the workplace?

Safety labels have a role to play during the packing, storage, transportation, and distribution of the product to the customer.

Let’s look into the top reasons why safety labels are important for all products:

The packaging is essential as it is used for the identification of the products in the market. The first thing that differentiates your product from your competitors is product packaging. It enhances the appearance of the label for promoting the product.

Marketers use unique labeling for their products to help in brand identification. This kind of labeling helps viewers to differentiate the product from the rest, on the shelves of the market. Apart from promoting brand identity, product labeling also helps in boosting product safety.

Labeling with appropriate safety labels is essential to ensure the safety of the person buying the product and other people who handle the product along the supply chain. Right from storing, transporting, and distributing the product, safety labels play a crucial role. It’s easy to identify hazardous and non-hazardous products with safety labels.

For example, consider a firework that is being transported across the country. The product safety label will have the following words in bold “Flammable Material: Handle with Care.” This makes it easy for everyone handling the product to take the necessary precautions.

Now that we’ve established the reasons why safety labels are important so let’s take a look at:

What is the Safety Label?

First things first – a safety label is usually attached to the product’s package, or placed directly on the product or printed along with the instruction manual. The safety label warns users about the risks associated with using that particular product. It may also contain certain restrictions on usage, as mentioned by the product manufacturer.

For instance, a mobile phone could have the following safety label from the manufacturer: Not to be used in extreme temperatures. This indicates to the users that they should avoid using the mobile phone in extreme environments to prevent it from malfunctioning.

What could happen if you don’t use Warning Labels?

The manufacturer must notify customers of possible risk or injury they may be subjected to when using the product. Lack of sufficient warning labels or using inadequate wording could land the manufacturer in trouble.

As a manufacturer, you are required to follow certain rules and regulations when printing safety and warning labels for your products. For instance, if your company manufactures hazardous chemicals, then you’re bound by law to label it accurately, as per industry standards.

Here are some common materials for which safety labels and hazard warnings are a must:

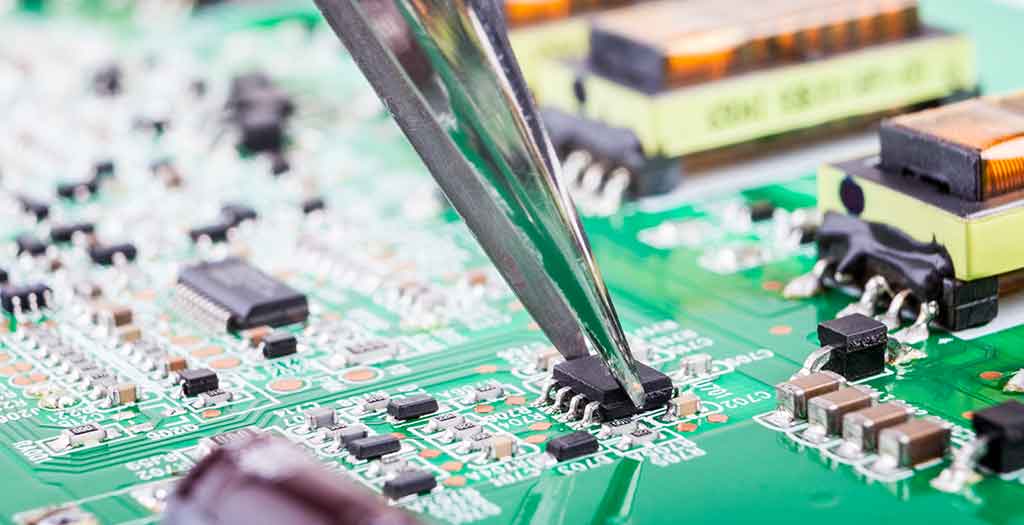

- Electrical and electronic components

- Flammable materials like gasoline, petrol, fireworks, etc.

- Medical aids

- Toxic substances

- And more

The Legal Perspective of Labels

Apart from the safety perspective, product labels are required by certain countries for selling your products in their region. Safety labels are a must for products like garments, toys for children, metals, foods, and more more.

The Placement of Labels

Not just the label wordings but also the placement of labels matters a lot. Proper label placement reduces the chances of miscommunication and potential injury. Here are a few tips for proper label placement:

- Ensure that the product label you use is visible and legible at all times.

- Color-code labels to make them easier to recognize from long distances. For instance, red is mostly used for hazardous products and black for toxic substances.

- Place labels and signs at eye-level for easy reading.

- Use labels that are water-proof and don’t fade easily.

- Use high-quality labeling supplies that can last well in harsh industrial environments.

If you need help, choosing the right labels for your products, our team here at Safix can help you out. With years of experience in the safety industry, we have worked with clients across niches. Get in touch with our team and put all your labeling woes to rest.